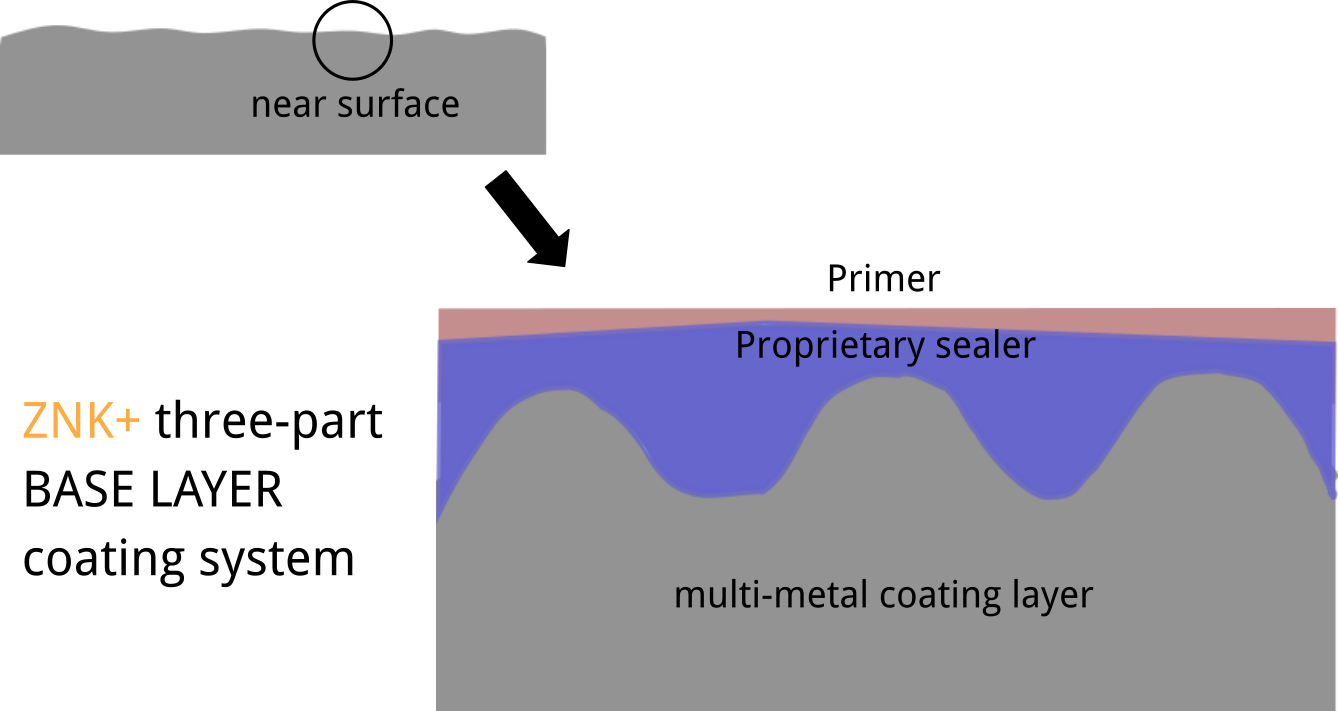

The complete metallic base layer is comprised of the multi-metal layer together with additional sealers, and optionally, primers to accommodate organic topcoats.

The passivation and sealing process is an important step in the mechanical galvanization of steel fasteners. This process helps to protect the galvanized coating from corrosion and other environmental factors, and can improve the performance and service life of the fastener.

The chrome-6 free passivation process involves treating the galvanized coating with a chemical solution that removes any residual contaminants and impurities from the surface of the coating. This is typically done using an acidic solution, such as a nitric acid or citric acid solution, which reacts with the metal surface to remove any contaminants and improve the corrosion resistance of the coating.

After the passivation process is complete, the fastener is completed with a clear, protective sealing coat. This coating helps to protect the galvanized surface from environmental factors, such as moisture, salt, and UV radiation, which can cause the coating to degrade over time. The sealant is typically applied using a spray, dip, or brush application method, and is allowed to cure before the fastener is shipped to the customer.

Overall, the passivation and sealing process is an important step in the mechanical galvanization of steel fasteners. It helps to improve the performance and service life of the fastener by removing contaminants and protecting the galvanized coating from environmental factors.